Exploiting Metal Mesh's Benefits for Your Goods!

Article Title: The Versatile World of Expanded Metal: A Strong and Efficient Mesh Material

In the realm of metalworking, expanded metal stands out as a unique and versatile material. This mesh-like substance is created through a process that involves slitting and stretching a single sheet or coil of metal, resulting in a strong, lightweight, and uniform mesh with openings tailored to specifications [1][3][4][5].

The Manufacturing Process

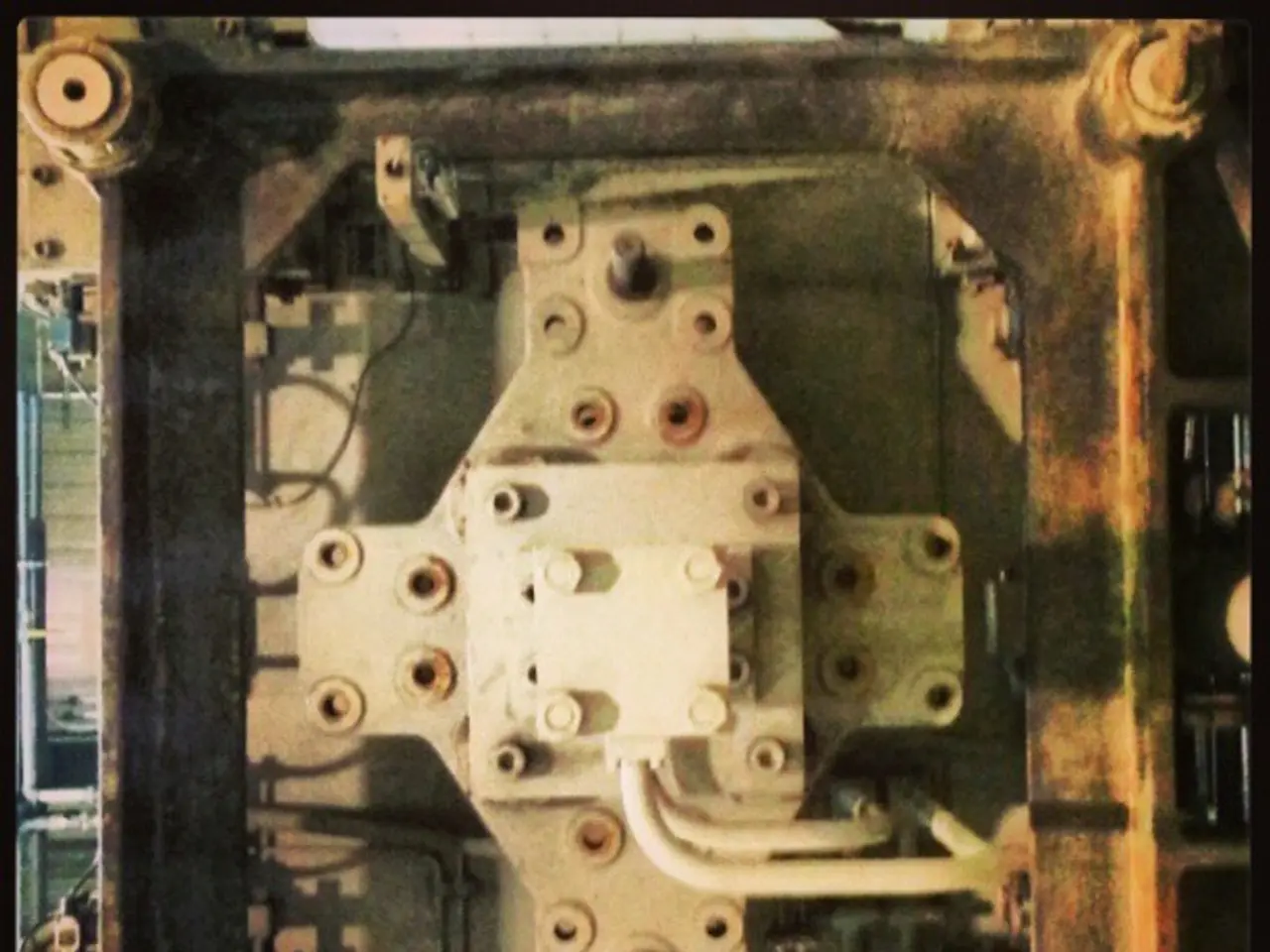

The transformation of a solid metal sheet into an expanded metal mesh is a fascinating process. A metal sheet is fed into an expanding machine, where it is subjected to precise, controlled slitting and stretching. The metal is slit into strands and stretched to form the characteristic openings, and then carefully rewound for ease of handling and further processing [1][3][4][5].

Applications Galore

Expanded metal's versatility is evident in its wide array of applications. In the industrial and architectural sectors, it is used in grates, stair treads, outdoor furniture, fencing, and architectural detail work, thanks to its strength and durability [4]. It also serves as a protective barrier in safety guarding, shielding people from hot surfaces or machinery [4].

In the realm of filtration, expanded metal supports and protects various media like non-woven fabrics and filter papers. It is the main filter material in air filtration, water purification, paint filtration, and oil filtration systems. The apertures can be customized to allow precise filtration, and the metal is resistant to corrosion when treated [2].

Expanded metal foil and mesh are integral components in precision applications requiring lightweight, strong, and uniform metal meshes without weak points [1].

A Shining Star in Modern Architecture

In the world of modern architecture, expanded metal is used to form decorative features and building facades, adding a touch of elegance and functionality to structures [6].

Built to Last

The strength of expanded metal makes it suitable for anti-slip constructions such as walkways, stair treads, and ramps. The sturdy knuckles formed by the strands ensure a non-slip surface [7].

Cost-Effective and Eco-Friendly

The manufacturing process of expanded metal results in minimal waste, contributing to its lower cost. This reduced waste also makes it cheaper to mold and use [8].

A Mesh of Options

The openings in an expanded metal mesh can take various shapes such as square, hexagon, diamond, and circle. Furthermore, it can be made from a variety of metals, including stainless steel, copper, aluminum, bronze, galvanized steel, brass, Monel, carbon steel, or brass, or an alloy of these metals [9]. The size of the openings can range from 1/8'' x 1/8'' to 6'' x 6'', catering to a multitude of requirements [10].

In essence, expanded metal is a strong, lightweight, and versatile mesh material with numerous applications, from industrial safety and architectural design to filtration and precision manufacturing [1][2][3][4][5]. Its eco-friendly manufacturing process, minimal waste production, and cost-effectiveness make it a popular choice in various industries.

Read also:

- Dinesh Master's Expedition: Acquiring Mango Orchard through Our Online Platform

- Expanded Plant-Based Protein Industry Forecasted to Reach a Value of $30.8 Billion by 2034, Growing at a Compound Annual Growth Rate (CAGR) of 7.1%

- London home transforms leftover materials into a striking architectural design statement

- Tested the premier MacBook docking station for home office use as a professional laptop reviewer