Innovative and eco-friendly bonding through cutting-edge technology

In a move to enhance the quality and precision of adhesive application in the packaging industry, Robatech has developed a new generation of adhesive application systems. The company's latest offerings, the Alpha adhesive melter and the Volta electric application head, are designed to offer energy savings and improved durability.

The Alpha adhesive melter, a compact yet powerful all-rounder, boasts a high melting capacity and a relatively small tank. It is backward compatible with heated hoses and application heads from the year 2000, allowing for step-by-step system modernization without replacing all components. This innovative melter offers energy savings of 46% compared to its predecessor.

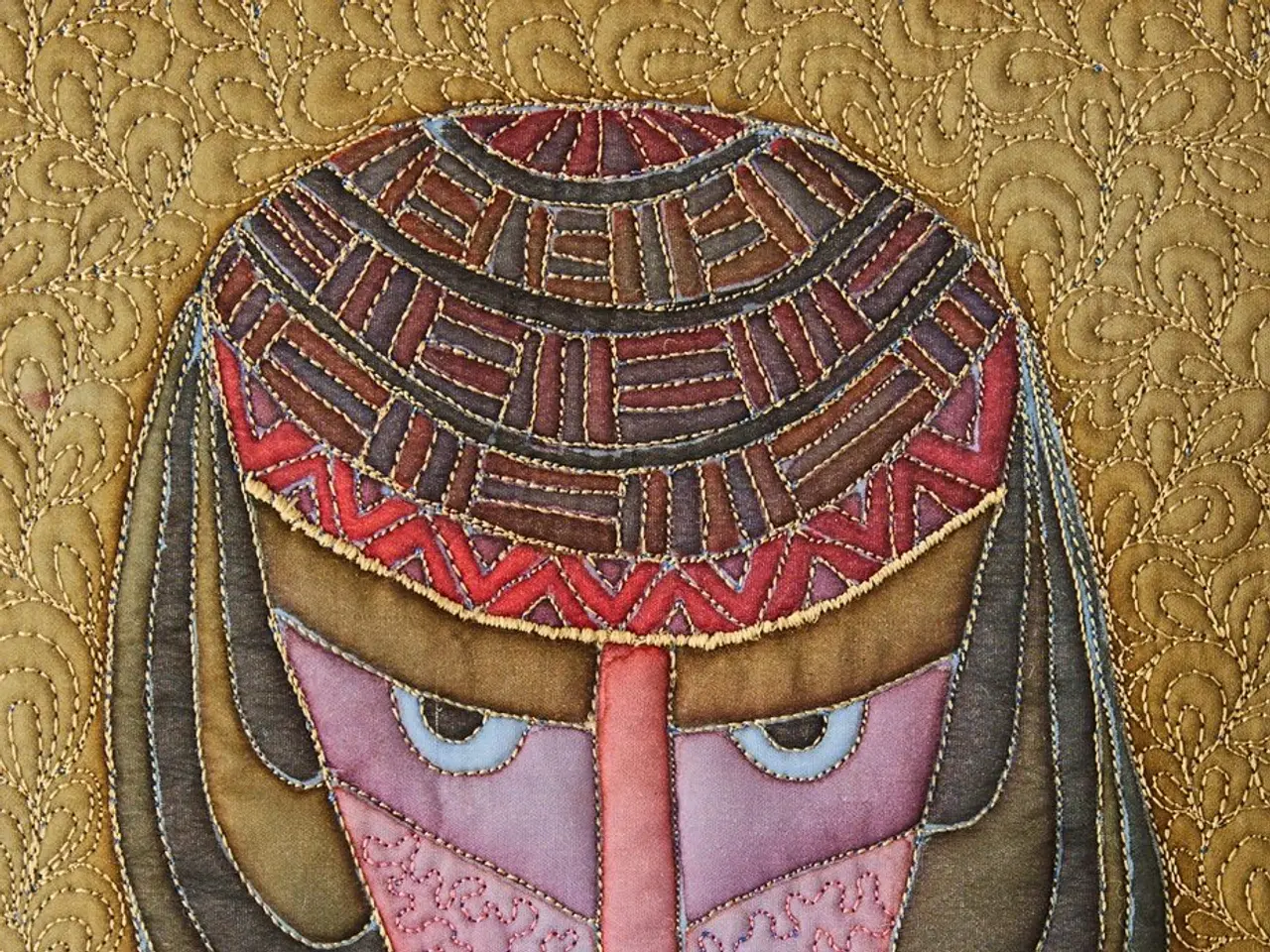

The Volta electric application head, on the other hand, is ideal for cost-effective and reliable gluing of both primary and secondary packaging. It consumes 60% less energy than conventional pneumatic heads and delivers exceptional durability, with over two billion operating cycles demonstrated. The head features an integrated stitching function, which breaks up adhesive beads into shorter beads or dots, allowing for up to 60% reduction in adhesive consumption without compromising bond strength.

Robatech addresses the challenge of energy consumption in adhesive application with the fully insulated Performa heated hose. Its high-tech insulation layer reduces energy consumption by 45% compared to conventional heated hoses. Furthermore, the quality and precision of adhesive application are improved with the use of the innovative plug-in coupling, PrimeConnect, in the Performa heated hose. This eliminates thermal bridges at both ends of the hose.

The Volta electric application head, however, requires more maintenance and is more prone to faults compared to compressed air systems. Despite this, the head offers significant cost-saving potential due to its reduced energy consumption and increased durability compared to pneumatic application heads.

The integrated Robatech Control System (RCS) simplifies system integration via standardized interfaces and offers intuitive operation, both directly on the melter or remotely. Rolf Gräser, industry manager for Packaging at Robatech, explains that the development focus was on the use of robust, energy-efficient components.

However, it is yet to be reported which companies currently use Robatech's new generation adhesive application systems Alpha and Volta in their production and the resulting cost and energy savings. Nevertheless, these innovative systems promise to revolutionise the packaging industry with their energy efficiency, durability, and precision.

Read also:

- Journey Across America: Travels from the Eastern to Western Coast

- Solar panels decreasing expenses and aiding ecological preservation

- Waste from grapes transformed into a robust substitute for plastic, degrades within seventeen days

- German government grants additional research funding to Rock Tech Lithium for continued lithium exploration and development projects.